-

Posts

1,065 -

Joined

-

Last visited

-

Days Won

40

Content Type

Profiles

Forums

Events

Everything posted by Rusty White

-

I agree, and to give credit where credit is due, that is as good as the NCC can come up with considering so many variations and new kits coming to market. I would suggest emailing the appropriate head judge or the Chief Judge (nationals or regional contest) for a more definitive answer.

-

Download the national rules from the web site and look under III. SPECIAL CATEGORIES (pg 3). Your questions will be answered.

-

Regardless what you may have heard, photo etched parts put out by manufacturers are REQUIRED by EPA regs to thoroughly clean the parts before they leave the factory. That's just one reason why PE parts are so expensive. I can only assume the same goes for imported parts as well. In other words, all photo etched parts are ready for painting or soldering right from the factory.

-

You may consider this. https://flagshipmodels.com/collections/how-to-cds-and-photo-albums/products/how-to-cd-working-with-photo-etched-parts-by-rusty-white-11-pgs

-

Has anyone ever determined exactly what the scale was of this kit?

-

FWIW, Flagship Models' business has increased roughly 25% since the pandemic began. I attribute it to more folks staying home.

- 25 replies

-

Welcome! Just a word of caution. The Corona virus has done real damage to the contest schedule. Check the current IPMS/USA calendar carefully before making plans to attend. 🙂

-

Those OLD dinosaur kits don't look bad when painted up properly. Nice job!

-

Final revisions have been made to the photo etch sheet and are currently at the etcher. Metal parts have been cast and are here, as well as wood masts, and yards. The instructions are nearing completion and I am now ready to begin making molds. It won't be long now.

-

From one who knows. Hospice is a wonderful service for the chronically ill and their families. God's speed to Bill and his survivors.

-

I don't know, and I'm sure there many modelers out there in the same state of confusion as I. Just an official statement from either the host chapter or the E-board would be nice.

-

Personally, I would like to hear IPMS/USA's official current position on the subject.

-

Not 2020..Contest results

Rusty White replied to wdedig's topic in About the IPMS/USA National Convention

"I would like to move this idea forward to IPMS Leadership. Any Ideas How ?" I got the GSB-123 survey going by first discussing it here. Ron Bell was looking in and contacted me. You have done that, so I would suggest next talking to the 2021 convention chairman and see how they feel about it. I say 2021 because you may not have time to get everything worked out with the 2020 Chairman and E-board to do it this year. You will NEED the support of the 2021 convention chairman if you have any hope of this going any further. If you can get support from the 2021 chairman, contact the 2nd VP as he is the liaison to the E-board regarding national convention matters. Without his support, it will be a real uphill battle. -

Not 2020..Contest results

Rusty White replied to wdedig's topic in About the IPMS/USA National Convention

No one asked us to try anything regarding the slide show in '03. Everything we did was of our own accord and we kept the 2nd VP informed. I agree that host chapters should not be "lab rats". We chose to be "lab rats", because we knew where the problems occurred previously. I was so concerned about the show failing that we held a Saturday 2000 slide (2000 slides) show at a local church using the exact set up we would be using at the Nats. It went flawlessly and we got to see some cool model slides. -

Not 2020..Contest results

Rusty White replied to wdedig's topic in About the IPMS/USA National Convention

I agree. Back in 2003 when I chaired the Nats in OKC, everyone I talked to said a slide show at the awards ceremony just couldn't work with programs available at the time. Guess what. We figured it out and the slide show came off without a hitch, WITH the program everyone had failed with before OKC Metro. Never be afraid to try something new and different. -

Not 2020..Contest results

Rusty White replied to wdedig's topic in About the IPMS/USA National Convention

Nice reply with some good ideas and suggestions. I like this thread. -

Clubs are not active web pages or facebook

Rusty White replied to RoyBatty's topic in Ask the IPMS/USA

I agree with Bill that many clubs now choose to host local shows that are less a financial and organizational risk than a regional show. -

Italian Flintlock Pistol by Lifelike 1:1 scale

Rusty White replied to Bennetts's topic in Miscellaneous Projects

I like to give everyone the benefit of the doubt because emails are misunderstood sometimes. Hopefully this post will die the death it should and go no further in this forum (hint, hint). -

What an unusual subject! Great looking base too. It looks really nice. Well done.

-

Price doesn't matter (to me) as much as availability. This is exactly why I started Flagship Models. Back in the day when I built exclusively modern and cold war era warship models, there were VERY few (if any) detail sets for those eras. I was sick and tired waiting for someone to issue the sets, so I produced my own. Back then the artwork had to literally be drawn by hand on Mylar sheets with Rapidograph pens (time consuming pain in the rump)! Since I now have the skill to MAKE a kit, since no one else will make one, I will.

-

The waterline option is one of the ways I'm trying to keep the cost down. As I said earlier, I have no idea what the final cost will be because I don't care. I have always wanted a Choctaw kit in a large enough scale to really appreciate it.

-

At this point in time there are too many "unknowns" I just don't know. Once all the parts are designed and test fitted, photo etch design begins, then 3D instructions, etc, etc, etc. Still lots of details to add to the parts. It gonna be a real beast.

-

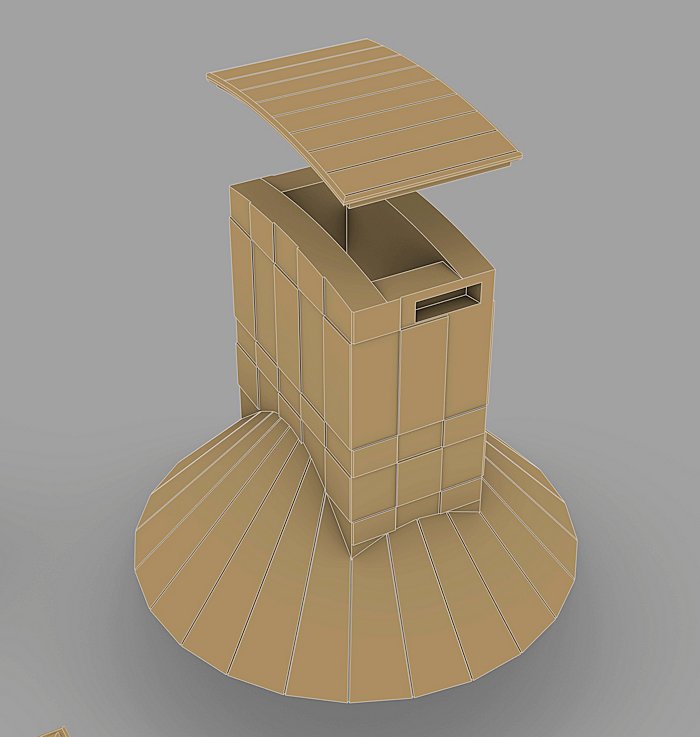

This will be Flagship Models' next, most advanced kit to date; the 1/192 scale USS Choctaw. It will be approx 18" long as a waterline hull option and will include a highly detailed PE sheet and decals. The drawings below are preliminary and yet to show the MANY additional details yet to be added. Price has yet to be determined, and personally I don't care what it is. This is a personal project that I want and I have received a number of requests from fellow modellers of the civil war era that they would like one, so I decided to add it to Flagship Models' line of kits. More as development continues.

-

Just make certain the chamber will be big enough for your mold.

-

With RTV (room temperature vulcanized) rubber for molds, I use a vacuum chamber to degas (remove the excess air) from the rubber before pouring the mold. Be sure to spray the mold box (or mold for the resin) with a release agent to make removing the mold from the master pattern easier. Resin is done in a similar manner except I pour the resin into the molds before degassing. This technique allows the resin to migrate into the smallest details of the mold.