Search the Community

Showing results for tags 'kit build'.

-

Hello all, Last time I tried this I didn't get too many responses and...even worse...I can't find the responses I did get! Well, live and learn. This time I'm gonna put the results in a folder on my computer's hard drive so I can't lose'em!! Now to what I'm asking about: Please offer your thoughts as to the model or models you would like to see as step-by-step e-books (one kit to a book, please). Your response matters. See scalepublications.freeyellow.com for current e-books. All ebooks will be available in a printable PDF format for those who prefer hardcopies. Subject? Kit Build or Photo Reference Gallery? Scale? Manufacturer (classic, out of production or current)? Standalone shelf model? Standalone on small base? Vignette/Diorama preferred? Include aftermarket components? Comments (Don't be shy, I want your thoughts)? Note that there are no restrictions on the quality of the kit or when it was originally produced. "The only game in town" kit will be given equal consideration.

- 9 replies

-

- survey

- kit survey

-

(and 3 more)

Tagged with:

-

I'm posting this so you won't keep wondering when the next installment is going to show up. It won't. If you're curious, private message me.

- 1 reply

-

- e2c hawkeye

- kit build

- (and 4 more)

-

Hi all, Here's the latest on the E2C 2000. The canopy was masked with Montex Mini Mask (# SM 48321). Not only do they fit perfectly, you get a double set so you can mask both the inside and outside if you choose. I got mine from Sprue Brothers, but the Montex website is montex-mask.com. One advantage to Kinetic's canopy approach is that it includes a section of the fuselage. Since the canopy isn't a perfect fit...probably the result of a replacement part due to a short shot in the kit...it allows you to putty and sand any problem seams with relative ease. Incidentally, unless the Kinetic policy has changed, when you request a replacement part, they won't acknowledge the request. Just send the part when they get around to running the kit mold again. This means that your needed part will eventually show up in your mailbox anywhere from a few weeks to a couple of months or more later. Remember I said the wing fold joints and nacelle/wing joints fit perfectly? Well, they do. Mostly. But when I looked close, I found a slight step in the starboard wing step joint and a similar problem with the nacelle/wing joints. This is likely the result of the kit parts fitting as tightly as they do and it's something you need to watch out for. In any event, the problem isn't severe and can be taken care of without losing much if any surface detail, which can be easily restored. The port wing joint, nacelle area just took a little sanding and no putty at all. Whether the bulged side window...which is a separate piece that has to be installed before mounting the canopy...shifted during canopy installation or I simply screwed up the initial installation, I can't say. In any event, I had to carefully cut out the window and reinstall correctly. As it turned out, at least on my kit, the window was slightly too large to fit properly so it took several test fits and very gentle trimming to get things right. The eight-blade props are built up from a pair of four-bladers. Each blade also has an engraved leading edge that needs to be painted steel. Checking references, the steel sections appear to be everything from dark steel to bright aluminum. How much of this is due to light reflection and/or viewing angle I can't say. So for model purposes I chose to go with Model Master Metalizer Non-Buffing Aluminum. In an earlier installment, i installed brass tubing in the nacelles in preparation for removable props. To complete that system, I installed a length of 3/32" (.094") tubing in the back of each prop. Length of the tubing doesn't matter, within reason, and you'll have to align the new shafts with ye olde Mk. I eyeball computer. Done right, they'll spin like a whirligig if you hold the model in front of a fan. One of the eight-blade props completely finished. The white tips are decals and are designed to fold over to create white tips both front and back. It works for the most part, but you'll probably need to do a little bit of touchup on the back with Model Master Flat White. I did. And of course manufacturers logos go on the front of each blade, positioned so that the beltline of the logo aligns with the bottom line of the steel/aluminum leading edge. The decals from the kit sheet are appropriately thin, but they take a long time to release from their backing sheet. Since there are a total of 32 decals for the two props, you should plan on a relatively extended decal session. Also, I wound up using tweezers to handle and position all of the logos and some of the tip decals. The side windows have been corrected and reinstalled. The canopy section/fuselage seam has been eliminated. Last but not least, Finally the nose cone was added. The nose cone is indexed with a locator pin. As a result, the bottom part of the seam is a perfect fit but the top seam requires a little sanding to bring things into line. With that done, all that's left is a final shot of primer, finish paint and decals. Incidentally, 'all' is not as simple as it sounds considering the large number of decals.

-

Hi all, Here's the latest on the E2C 2000. The canopy was masked with Montex Mini Mask (# SM 48321). Not only do they fit perfectly, you get a double set so you can mask both the inside and outside if you choose. I got mine from Sprue Brothers, but the Montex website is montex-mask.com. One advantage to Kinetic's canopy approach is that it includes a section of the fuselage. Since the canopy isn't a perfect fit...probably the result of a replacement part due to a short shot in the kit...it allows you to putty and sand any problem seams with relative ease. Incidentally, unless the Kinetic policy has changed, when you request a replacement part, they won't acknowledge the request. Just send the part when they get around to running the kit mold again. This means that your needed part will eventually show up in your mailbox anywhere from a few weeks to a couple of months or more later. Remember I said the wing fold joints and nacelle/wing joints fit perfectly? Well, they do. Mostly. But when I looked close, I found a slight step in the starboard wing step joint and a similar problem with the nacelle/wing joints. This is likely the result of the kit parts fitting as tightly as they do and it's something you need to watch out for. In any event, the problem isn't severe and can be taken care of without losing much if any surface detail, which can be easily restored. The port wing joint, nacelle area just took a little sanding and no putty at all. Whether the bulged side window...which is a separate piece that has to be installed before mounting the canopy...shifted during canopy installation or I simply screwed up the initial installation, I can't say. In any event, I had to carefully cut out the window and reinstall correctly. As it turned out, at least on my kit, the window was slightly too large to fit properly so it took several test fits and very gentle trimming to get things right. The eight-blade props are built up from a pair of four-bladers. Each blade also has an engraved leading edge that needs to be painted steel. Checking references, the steel sections appear to be everything from dark steel to bright aluminum. How much of this is due to light reflection and/or viewing angle I can't say. So for model purposes I chose to go with Model Master Metalizer Non-Buffing Aluminum. In an earlier installment, i installed brass tubing in the nacelles in preparation for removable props. To complete that system, I installed a length of 3/32" tubing in the back of each prop. Length of the tubing doesn't matter, within reason, and you'll have to align the new shafts with ye olde Mk. I eyeball computer. Done right, they'll spin like a whirligig if you hold the model in front of a fan. One of the eight-blade props completely finished. The white tips are decals and are designed to fold over to create white tips both front and back. It works for the most part, but you'll probably need to do a little bit of touchup on the back with Model Master Flat White. I did. And of course manufacturers logos go on the front of each blade, positioned so that the beltline of the logo aligns with the bottom line of the steel/aluminum leading edge. The decals from the kit sheet are appropriately thin, but they take a long time to release from their backing sheet. Since there are a total of 32 decals for the two props, you should plan on a relatively extended decal session. Also, I wound up using tweezers to handle and position all of the logos and some of the tip decals. The side windows have been corrected and reinstalled. The canopy section/fuselage seam has been eliminated. Last but not least, Finally the nose cone was added. The nose cone is indexed with a locator pin. As a result, the bottom part of the seam is a perfect fit but the top seam requires a little sanding to bring things into line. With that done, all that's left is a final shot of primer, finish paint and decals. Incidentally, 'all' is not as simple as it sounds considering the large number of decals.

-

Hi all, Moving right along, here's the next installment. As you know, the horizontal is not horizontal but is instead a very mild V shape. I've rotated the image in order to show you that the inboard verticals form a 90 degree angle to the horizontal. This means that the inboard verticals actually lean in toward the aircraft centerline, as do the tip mounted verticals. The easiest way to get all of the verticals installed correctly is to simply cut a 90 degree piece of scrap styrene and use it as a square. With both inboard verticals installed, you can see how they're supposed to look when properly aligned. In this view from the top, the tail assembly in complete. And for the hawkeyes (pun intended) in the crowd, two of the molded static discharge wires are broken. No matter how careful you are, odds are you're gonna break at least one before you're thru. A little later I'll show you my repair method. With all of the verticals installed and viewed from the back, that is one busy tail section. And it gets even busier when the wings are folded! Incidentally, the slots and tabs for the inboard verticals are keyed but the end ones are not. Since logic says that the verticals should be higher above the horizontals than below it, you'll need to be careful to position these correctly. Also, the slots tend to be a little snug, so you may have to ease them a bit for proper fit. Finally, in my case, I had to shorten the inboard vertical tabs so that they would seat correctly. Regardless of how complex the radome support looks, it's actually a piece of cake, utilizing a mere four pieces. This is the port side. And the starboard side. The rough area you see is dried liquid styrene that squeezed out during installation. It'll be cleaned up in due time. I shot some Dupli-Color Gray Primer over the area that would be covered by the installation of the radome support and then attended to any remaining seam flaws that might exist. After that, a final shot of primer and I was ready to install the support. Installation of the support is a little on the tricky side, but in this case patience is a virtue. As you can see, it does fit the way its supposed to. More than likely the four holes in the fuselage top will have to be 'adjusted' a tad with a #11 blade, but don't get too ambitious at one whack. Adjust and try is the watchword here. Looking down, you can see how everything finally fits the way it should. After all the solvent has dried, the support is sturdy enough to pick up the entire model with it. That's saying something when you consider how much lead this model takes to keep the nose down. One more thing: In case you're wondering about that collar that projects above the top of the support, it's supposed to be there. It's a spacer that allows the radome...both real and model...to rotate without binding on the top of the support. And for us, it has one other very useful benefit. Due to the way this kit is designed, not only will the radome rotate (by hand, of course), but it is also removable as long as you don't glue the shaft in. That's a real advantage when it comes to transporting the model and especially when shipping it to a client in another state.

-

Hi all, It's been a while, but here's the sixth installment on the E-2C. Here I needed a little more seam work than just a light touchup. So, as I frequently do in order to protect adjacent detail, I laid down a couple of strips of blue masking tape before sanding the seam. With the seam taken care of and the tape removed, I still needed to finish the seam with 600 grit or so sandpaper. Going that fine wouldn't have any deleterious effect on the surrounding detail. Taking a break from the fuselage, the side windows and overhead hatches were tinted a translucent gold color by mixing a combination of Tamiya X-22 Clear, X-26 Clear Orange and X-24 Clear Yellow acrylic, along with the tiniest dot of X-19 Smoke acrylic. This was strictly an eyeball mix. When I had something that looked right, the windows and hatches interiors were airbrushed while they were still on the sprue. Next up is attaching the outer wings. Believe it or not, they slip right into place with minimal adjustments. Here you can see how the finished installation looks. And yes, the fold joint forms a perfectly smooth connection as it should. I ran into something when installing the horizontal tail that I didn't expect. When you're holding the part in place before applying solvent, the locator pins fit as they should and you can hold the horizontal in the correct position. But, as soon as solvent is applied, the little beast wants to cock to one side. I wound up having to use a rubber band to hold it in place and even then I wound up checking, rechecking and making minute adjustments until the solvent set so that the entire tailplane would be correctly level after final assembly. I have no clue as to why it behaved that way. All I can say is watch it!

-

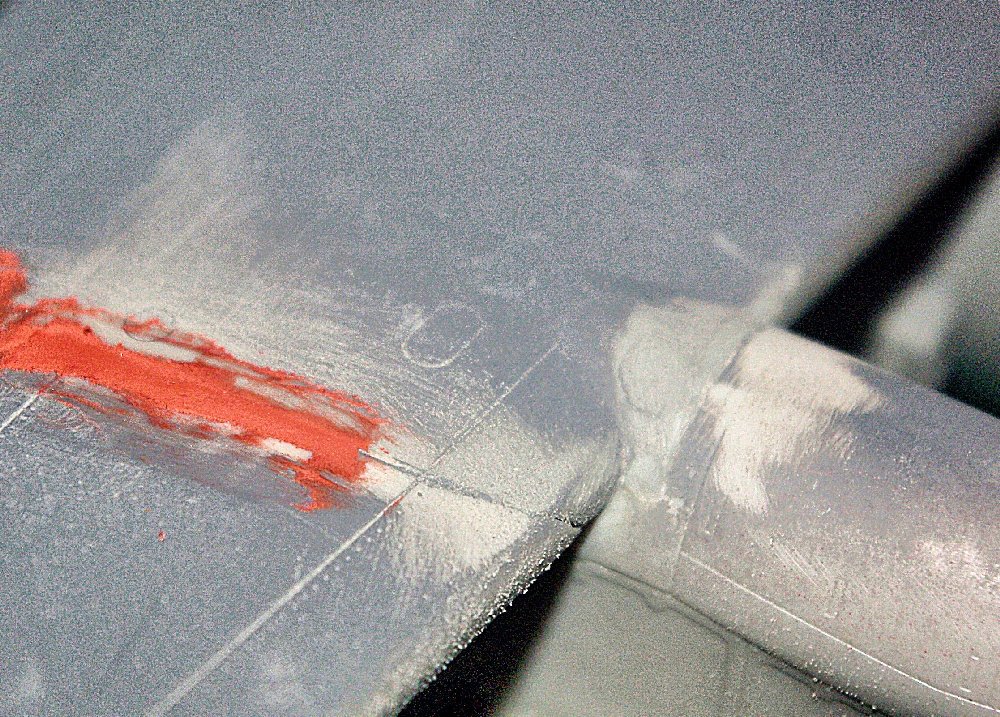

Hi all, Here's the latest progress on the Kinetic 1/48th E2C 2000. A recess in the bottom of the fuselage gives you the option of replicating the CEC (Cooperative Engagement Capability). This is the route I needed to go and I didn't anticipate any problem. I was wrong. It turned out that when the CEC insert is properly aligned, there's a .020" gap on the port side. Press the insert down for a tight fit and you wind up with a slight step in relationship to the fuselage. The solution is simplicity itself. All you need is a .020" x .030" Evergreen strip to fill the gap. If you're careful, all you'll need is a very light touch with a sanding stick to blend everything together. Now for the fun...installation of the wing center section. While the center section fits as it should, you won't be able to simply drop it in place and add solvent. In this shot, the center has been installed and snugged down with a couple of rubber bands. Here's a closer view of what it took to attain a proper installation. The aft end of the center section has to be pulled down with a rubber band that wraps around the fuselage. Because of this, you want to make sure the CEC is thoroughly dry before doing so. Then another rubber band goes under the fuselage and up over the wing stubs. Seen from the side, you get a better view of exactly the rubber bands were used to pull the center section down. Also, notice the internal detail thru the crew door. There's no interior detail in the fuselage beyond the cockpit other than this insert that allows you to position the door open if you choose. When everything's dry and the rubber bands are removed, you'll discover two problems in the form of seams that have to be filled. One, the largest, is at the aft end of the center section where you had to use the heaviest rubber band. The other's at the front and doesn't go all the way across. Just like the gap on the CEC insert, a strip of .020" x .030" Evergreen strip solves the problem. And the same thing up front. If you're careful, you'll barely need any sanding at all. The port nacelle is next and you will definitely need more rubber bands. Take a close look at this shot and you'll see that the heavier rubber band goes over the seam between the nacelle and the wing, then under the nacelle. In order to have continuity from the wing to the nacelle without a step, this is essential. Then another rubber band loops under the front of the nacelle,over the wing and under the aft part of the nacelle. This pulls the aft part of the nacelle up into position. Everything fits exactly as it should, but it takes this approach to get it there. Just in case you're confused by my previous description, this side view should help clarify things. I repeated the process for the starboard nacelle and finally wound up with what you see here. When everything dried and the rubber bands were removed, I was looking at a perfectly fitted wing center section and a pair of nacelles. Next installment you'll see how well things worked out before we tackle the canopy.

-

Hey all, It's been a while, but the C-46 is done and shipped. So now it's back to the Kinetic 1/48th kit of the Northrop Grumman E2C Hawkeye 2000. Some of you may find it helpful to go back and review the first three installments of this build. As with the C-46, this is a commission build for another client. O.K., y'all up to speed? Then let's see if I can get you a ways farther down the road. Besides the normal canopy, the E2C has three round windows located in the starboard fuselage. Kinetic provides individual inserts that fit perfectly. Due to the extended tab attached to each window, there's no problem with solvent fouling the clear. On the outside, these are some of the easiest windows I've seen to mask. Slap a piece of blue masking tape over each, run your fingernail around the window seam, follow that with a #11 blade and you're done. Whether you opt for extended or folded wings, that large radome guarantees that this little critter is a tail sitter and then some. Since there's enough room, l picked up a package of self-adhesive lead weights from Great Planes....try your radio control airplane shops if you can't find them elsewhere. With the cockpit installed in the starboard fuselage, I packed in close to a full ounce of lead in front of and behind the cockpit. The white arrows show you exactly where. Since each 1/4 ounce piece has VERY sticky tape on the back, you won't have to worry about the weights coming loose. But do be sure you have'em where you want'em before applying pressure because you won't be gettin' them loose. Another 3/4 ounce or so of lead was added to the port fuselage. Not only did this make sure that it wouldn't tail sit, it also tells you why those Scale Aircraft Conversion metal replacement gear are essential. If you haven't had an Oops! event while working on models, you haven't been building very long! Here I got ahead of myself and joined the tail end of the fuselage before adding the tail hook well. Fortunately the solvent hadn't cured too long, so a lot of care and a new #11 blade made splitting the aft fuselage fairly easy. Rather than split the entire fuselage, I wrapped a rubber band around the fuselage about halfway up, then shoved a spring clothespin into the gap to keep the fuselage halves separated,. With the tail hook well properly installed, the fuselage halves were rejoined and a rubber band along with another spring clothespin was used to keep everything snug until the solvent dried. Partly because of its size, the fuselage is not one that can be held together and watch the seams disappear. I had to work my way around a few inches at time, as well as employing the assistance of a number of rubber bands as I went.

- 2 replies

-

- 1

-

-

- kinetic

- 1/48th scale

-

(and 6 more)

Tagged with:

-

Installment #8 of the Williams Bros C-46 build is now online in the Builds sub-forum. Comments are welcome.

-

- 1

-

-

- Williams Bros

- C-46

-

(and 5 more)

Tagged with:

-

For those who are interested, linstallment #7 of the Williams Bros C-46 build is now online in the Builds sub-forum. Comments are welcome.

-

- Williams Bros

- C-46

-

(and 4 more)

Tagged with: